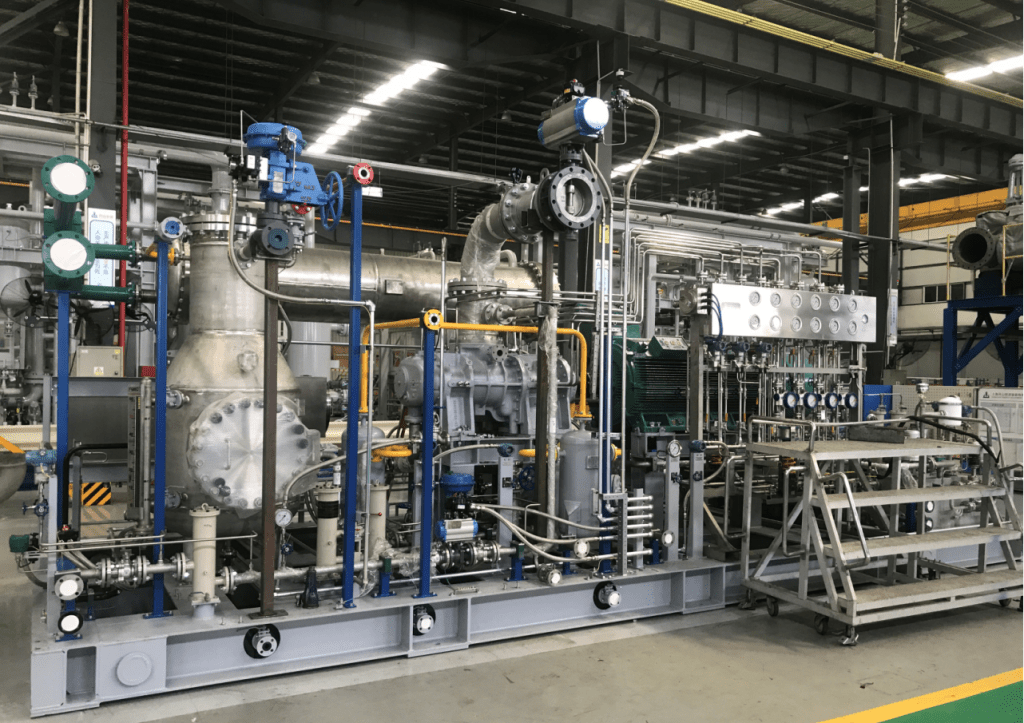

Dry screw compressor systems do not inject lubricating oil into the compressed air chamber, providing pure, oil-free, and dust-free compressed medium. They are commonly used to compress flammable, explosive, and toxic gases.

Innovative airend design:

The air-end features a “Y” rotor profile with cylindrical and tapered roller bearing triple design. The bearing life exceeds 100000 hours, ensuring super first-class reliability and service life. The low-speed large nose design offers stable performance, lower noise levels, and convenient installation due to its integrated design.

Applications:

– Petrochemical industry

– Refinery

– Chemical plant

– Coal chemical industry

– Energy industry

Scope of supply:

– Inlet pressure: -0.085 ~ 0.8 MPa

– Discharge pressure: 0.15 ~ 2.0 MPa

– Air displacement: 10 ~ 1380 m3/min

Technical features:

The excellent design of the rotor profile, poppet valve, and optimized orifice ensures high efficiency and energy-saving lifting units.

No gearbox is required due to the smaller rotor diameter.

Large bearing diameter and short aspect ratio effectively reduce noise levels.

Direct drive without rectangular sealing strips results in low exhaust flow rate and tip speed while ensuring high unit reliability.

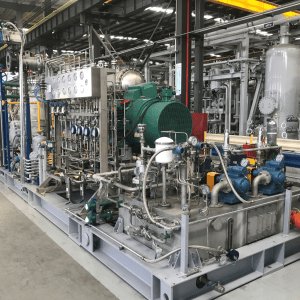

Oil injection screw compressor systems exhibit superior performance with reliable operation, low vibration levels, low noise emissions,

high efficiency rates,

and no vulnerable parts.

The unique lubrication method simplifies the mechanical structure while enhancing air tightness.

Applications:

-Petrochemical applications

-Fuel gas

-Acid hydrocarbon gas

-Dangerous gas

Scope of supply:

-Inlet pressure: -0.05~0.8 MPa

Discharge pressure:0.2 ~4 .O MPa

Air displacement:2 .2~150 m3/min

Technical features:

Customized orifice with variable content ratio allows for automatic matching back pressure, reducing power consumption and improving efficiency.

Modular design with full skid-mounted layout ensures a compact structure that is easy to deploy quickly.

Perfect integration of electrical and control systems enables internet-based remote monitoring for easy management.

Types of gas handled:

Coke oven gas, coal mine gas, natural gas, coalbed methane, methane, ethylene,

styrene,

blast furnace gas,

butadiene,

acid hydrocarbon,

steam recovery,

steam,

decomposition gas,

nitrogen,

acetylene,

lime kiln gas,

hydrogen

carbon dioxide

flare gas

ethane

propylene

propane

ammonia

chlorine

carbon monoxide

visbreaking furnace exhaust gas

cryogen

fuel gas

helium

hydrocarbon mixture

butane

methane

acid gases

other gases.