Recently, the aromatic hydrocarbon combined screw heat pump device developed by China Shipbuilding Industry Corporation 711 Institute has been successfully put into operation at Fujian United Petrochemical Co., Ltd. and Sinopec Jiujiang Branch. gas powered rotary screw air compressor

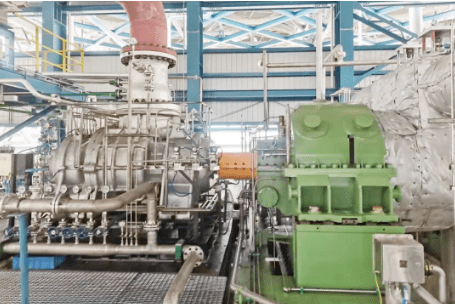

Sinopec Jiujiang Branch Project Site

Since 2016, the 711 Institute has been conducting research on screw-type steam compressors. It has also collaborated with Sinopec Engineering Construction Co., Ltd., Sinopec Jiujiang Branch, and Fujian United Petrochemical Co., Ltd. to develop a new generation of screw-type steam compressors for aromatic hydrocarbon integrated units.

After more than two years of technological breakthroughs, we have overcome various technical challenges such as high temperature and high pressure differentials. We have successfully developed a large flow rate, high discharge pressure, and high power screw-type heat pump unit with independent intellectual property rights. Once this unit is put into operation, it can reduce the energy consumption per ton of PX in aromatic hydrocarbon units by nearly 50%. This achievement holds significant practical significance for enhancing the profitability and competitiveness of China’s aromatic hydrocarbon industry.