Recently, the 300kW-level supercritical carbon dioxide (sCO2) Brayton cycle power generation system, jointly developed by China Shipbuilding Industry Corporation’s 711 Institute and other units including Shanghai Electric Power Generation Group, has successfully undergone testing and generated electricity. This achievement has laid a solid technological foundation for the future engineering application of this technology.

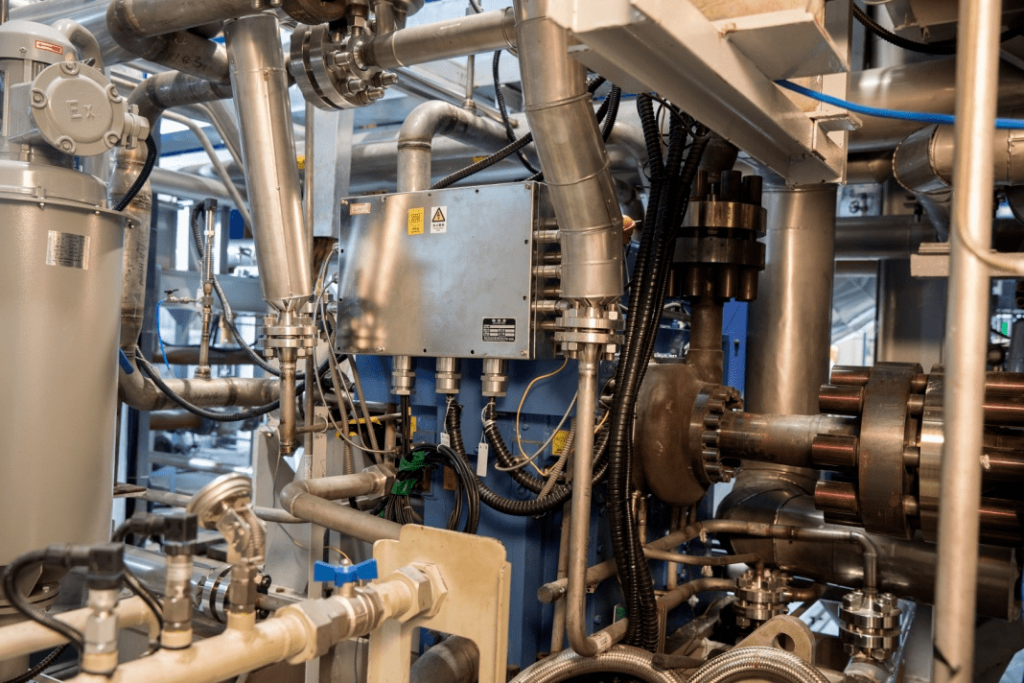

After three years of scientific research and development, the project team at 711 Institute has successfully overcome multiple key technologies including system overall design and performance simulation, process gas screw compressor-turbine integration design, efficient flow and heat transfer in sCO2 (supercritical carbon dioxide), high-speed high-pressure shaft end sealing, as well as manufacturing processes for critical components. They have completed the development of a prototype for a 300kW-level sCO2 Brayton cycle power generation system.

sCO2 cycle power generation technology is a closed-loop turbine power generation technology that uses carbon dioxide as the working fluid. Compared to traditional thermal power generation technologies such as steam cycles, it has significant advantages such as higher power density, higher thermal-electric conversion efficiency, and better flexibility in heat sources. It holds broad prospects for applications in areas like ship propulsion.