Who We Are?

In 1995, the company got involved in process gas compressors and established Shanghai Kaishan Process (Gas) Compressor Co., Ltd. The following focuses on the company’s process gas compressor business:

(1) Development history

The delivery of the first oil field semi-gas screw compressor unit in 2011 marked the beginning of Kaishan’s entry into the field of special gas compressors other than air. In the past ten years of development, Kaishan has always adhered to customer needs and innovative process technology needs as its own responsibility, optimized screw profiles, and promoted the upgrading of process gas screw compressors to large-scale and high-pressure directions.

The transformation and upgrading of large-scale equipment and machinery manufacturing to high-tech, high-value-added process gas compressors does not happen overnight. Kaishan leverages its own technology research and development advantages to integrate the entire industrial chain manufacturing resources of compressors of the group company. The first-generation process gas compressor has already highlighted its advantages in terms of low vibration, low noise, and high energy efficiency. With its excellent performance, Kaishan process gas screw compression The machine has been widely used in many fields such as petroleum, natural gas, refining, chemical industry, coal, hydrogen production, metallurgy, fermentation, harmful gas control, carbon capture, scientific experiments, etc.

(2) Technical advantages a) The internationally leading screw profile system Kaishan has a R&D team and independent development capabilities for the core profile of screw compressors. It continues to invest in the research and development of rotor profiles, and has the same 3 as internationally renowned profile R&D companies: 5, 4:6, 5:6, 5:7 and other self-developed molding lines with different structural types. In order to cope with the growing demand for process routes, the team developed the process gas screw compressor with the highest pressure and largest flow rate in China, which can well cope with the needs of different flow rates, pressures, and changing media components in the field of process gas compressors. Choose the best stable and efficient rotor profile to provide customers with highly matched compressor products, create value for customers, and expand the application scope of screw compressors.

(3)Domestic first-class compressor system design General Machinery Research Institute has a professional process gas compressor design team that carries out work from compressor host design, system process calculation, electrical instrument control integration, structural design, computer simulation analysis, etc. , providing a full range of work for process gas compressor projects from solutions, project management, delivery and commissioning. Combining the advantages of Kaishan gas compressors and customer needs, the team can quickly adjust and optimize the characteristics of the required products, provide customers with highly matching products, improve the application level of compressors in process equipment and gas pressurized transportation processes, and bring customers Come to more stable and efficient special gas compression products.

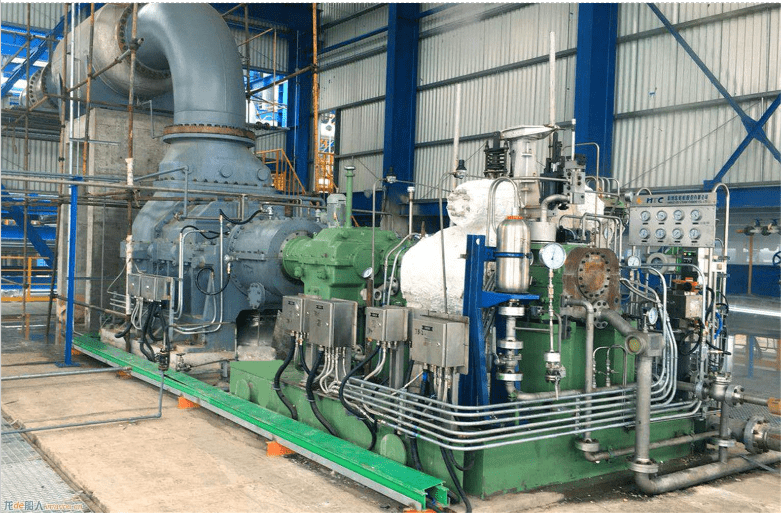

Domestic first-class screw compressor manufacturing system. From 2011 to the present, we have continued to invest in the construction of the manufacturing system for large-scale process gas screw compressors. We have built and owned four sets of dedicated screw rotor machining centers with a maximum processing diameter of 1m, and multiple sets Large-scale vertical integrated processing equipment for compressor pressure shells, as well as supporting infrastructure such as three-dimensional coordinate testing equipment and performance testing platforms, provide all-round support for process gas screw compressors from design, manufacturing to testing. , and also provides a guarantee for the continuous improvement of the technological iteration of screw compressors.

Comprehensive solutions Kaishan relies on a strong R&D system and a complete compressor industry layout. It has screw compressors, reciprocating compressors, screw expanders, industrial refrigeration and other products. With the new chemical process technology and gas treatment technology New demands for equipment, such as hydrogen energy, CCUS, gas separation and purification, etc., provide customers with comprehensive, professional and personalized overall equipment system solutions such as gas boosting, process industry refrigeration, and comprehensive utilization of thermal energy.

Refining, chemical industry, natural gas, petroleum refining tail gas, analytical gas, process raw gas, coal chemical industry and other applications;

In this field, oil-free process screw compressors have many applications. The equipment manufacturing and inspection of project products are carried out based on API standards to provide users with high-reliability products.

Natural gas, coal bed methane, oil and gas separation and other applications; oil-injected screw compressor products are widely used in this field. Based on the user’s usage area and the “remote, remote and scattered” application characteristics of the environment, the overall skid-mounted design is adopted to achieve unattended operation. , operates around the clock, greatly increasing the value of the product.

Iron and steel metallurgical industry.

Our Core Values

A heavy-duty compressor that works for you