Gas powered rotary screw air compressor

According to reports, styrene is an important raw material for the synthesis of high polymer materials and a fundamental product in the petrochemical industry. It is also one of the most commonly encountered compounds by humans. From space shuttles to sports shoe soles, from medical devices to commodity packaging, styrene is indispensable.

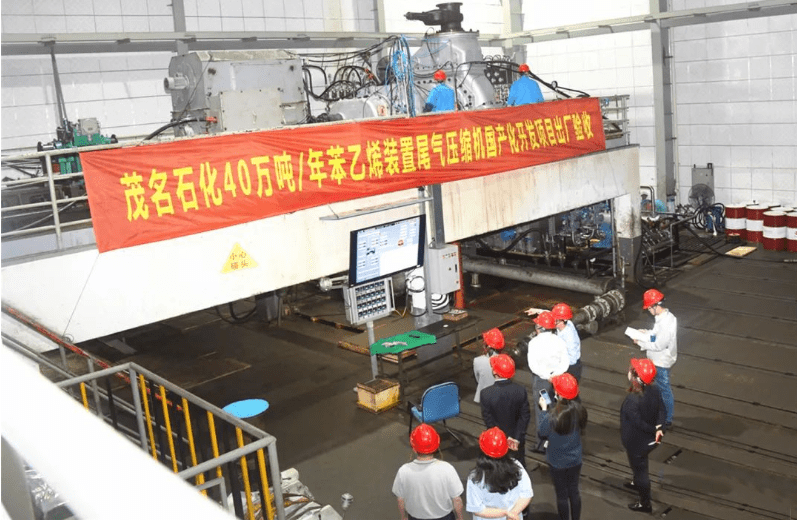

It is reported that in the field of large-scale styrene plant manufacturing in China, tail gas screw compressors have been a long-standing factor restricting the development of related complete equipment technology. Therefore, with the support of Sinopec’s Shanghai Engineering Company, Maoming Branch and 711 Institute, as well as relying on Maoming Petrochemical’s 400,000 tons/year crude pyrolysis gas-to-ethylene/benzene project, China Petroleum & Chemical Corporation (Sinopec) Major Equipment Localization Office has carried out domestication work on large-scale high-temperature styrene tail gas screw compressor units. After more than a year of research and development efforts by the project team, they successfully completed the unit’s development tasks.

During this acceptance work process, various tests such as screw compressor temperature rise test and mechanical operation test were conducted on this unit. All indicators met the requirements for factory acceptance. Subsequently, experts from the acceptance committee listened to reports on key technical breakthroughs for this project as well as information regarding project execution supervision and testing. They unanimously agreed to pass the factory acceptance.

The successful development of this unit will fill a gap in domestic production and break through import monopolies. It holds significant importance in reducing energy consumption levels for domestically produced process packages.