Process screw compressor Oil Free Screw Compressor Packages

Complete package systems for process critical applications

Durability and reliability Extremely heavy-duty industries need extremely hard-working compressors.

Oil and gas, iron milling or petrochemical processes are intensive and downtimes expensive.

Our process gas screw compressors can do the heavy lifting.

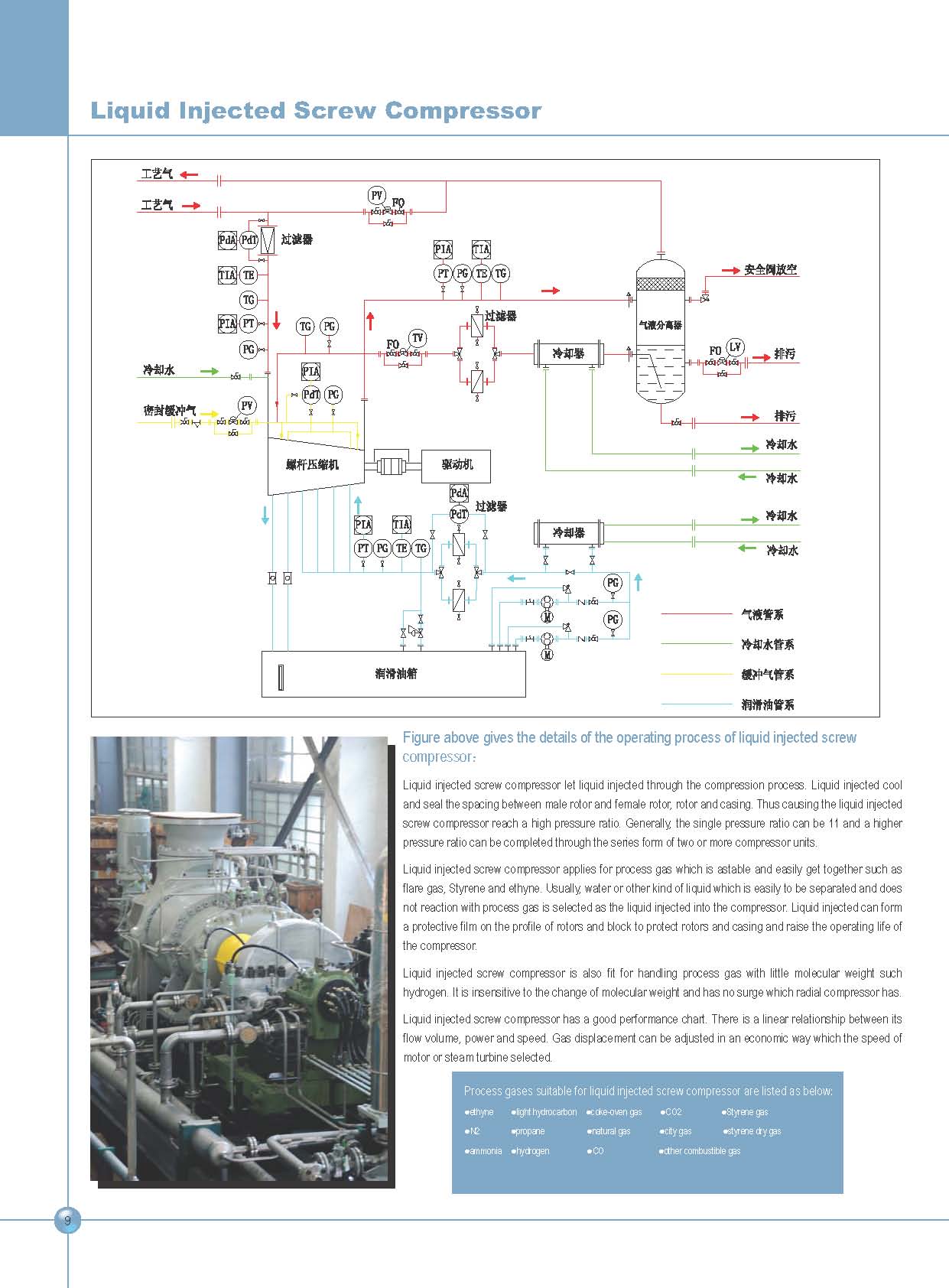

At present, process gas screw compressor is widely used in atmospheric and vacuum distillation, tandem reforming, liquid gas recovery and torch gas recovery systems for petrochemical

and oil refining industries. Usually, operating condition for such system is hard. E.g., the process gas may contain liquid, solid particles or corrosion gas such as hydrogen sulfide; the composition level of Hydrogen is high; or the gas component change frequently and etc. This caused the plunger and valves on reciprocating compressor need being replaced and maintained frequently in the past. However, the fluid injected screw compressor can resolve these problems well.

Advantages of liquid injected screw compressor

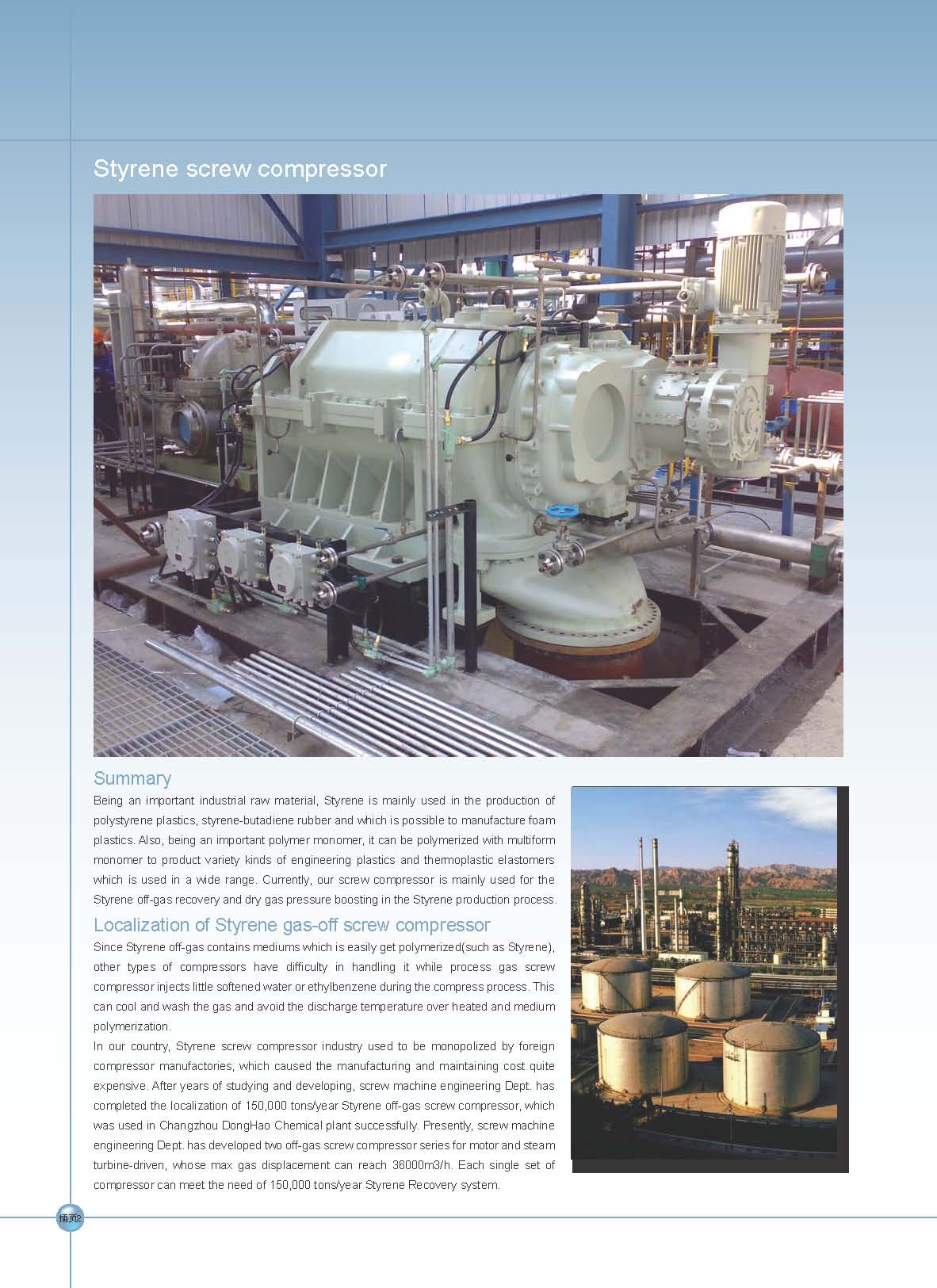

Liquid injected process gas screw compressor takes little care about the change of the gas composition, mole mass or the pressure ratio; it can also compress gas with very little

molecular weight and keep a normal operating when the Hydrogen content in process gas changes hard.

Rotors of liquid injected screw compressor don’t touch each other and keep a suitable gap through the synchronizer gears.

Liquid will be injected during the compress process to cool and wash the rotors, thus the compressor can be applied in compressing gas which is instability or easily got polymerized.

Liquid injected can also seal the gaps between rotors, gaps between rotors and shell to raise the volumetric efficiency of the compressor.

Liquid injected screw compressor has a high reliability. It can keep a continuous and trouble-free operation over 24000 hours in most conditions.

Performance Features of Process gas screw compressors

– Oil free compression

– Highest availability and reliability

based on very robust design

– Customized for specifi c process

requirements

– Ideal for variable molecular weights

– Dirty and polymerising gases

– Long overhaul inter

Oil Free Compressor Range

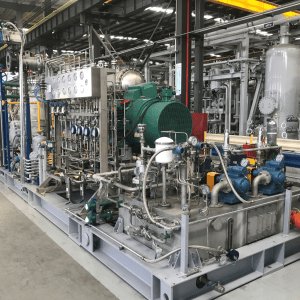

Oil Free Screw Compressor packages are used in processes such as:

Vapour recompression

Gas Liquefaction

Flare Gas Recovery

Gas Gathering

Sour Gas Handling

The oil free compressor range is able to provide gas compression to up to discharge pressures of 45 bar (653 psi) and 15 bar (217 psi) differential pressure. Available in 10 models the range covers flows up to 92,000 m3/h (54,150 cfm).

– Oil & gas production

– Refinery operations

– Flaregas recovery

– Butadiene extraction

– Styrene monomer production

– Hydrogen purification

– Power generation

– Soda Ash production

– Steel production (Coke Oven Gas)

– Refrigeration systems

Additionally, they can effectively handle gases such as hydrogen sulfide, methylchloride, chlorine, and hydrocarbon mixtures.