Time flies, Shanghai Kaishan Gas Compressor Co., Ltd. has gone through ten years since its establishment in 2012.

Looking back at the beginning, the original intention of the group’s decision to launch the gas compressor business was to apply its leading patented molding line technology to professional fields such as petroleum, natural gas, refining, and coal chemical industries, and to take advantage of its performance advantages such as high efficiency, low noise, and stability. This will achieve technological upgrading in the field of process compressors in my country and develop the process (gas) compressor business into a pillar industry of the group. After ten years of hard work, Kaishan Gas has achieved a transformation from scratch to excellence.

The road is blocked and long, but the road is coming. Entering the field of process gas compressors with high technical content and high added value is by no means an overnight success. However, Kaishan took advantage of its own technological research and development advantages and worked hard to achieve breakthroughs from 0 to 1 and from 1 to 10 in various industries and different application fields, turning Kaishan’s process compressor business into a butterfly and opening up a rapidly developing market. aisle.

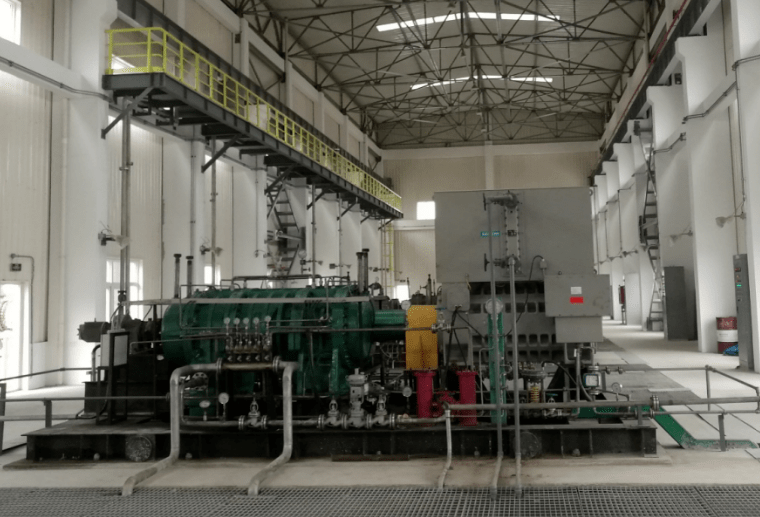

Kaishan process gas compressor has highlighted its advantages in low vibration, low noise and high energy efficiency, and has become a model for customers in the industry to visit.

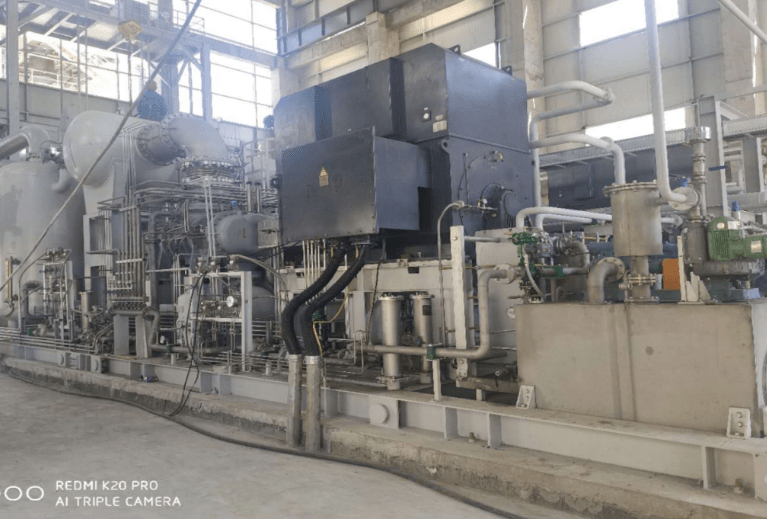

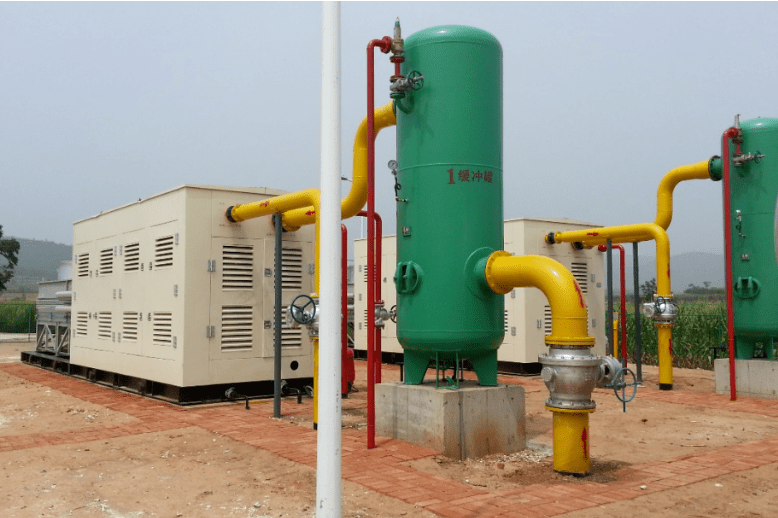

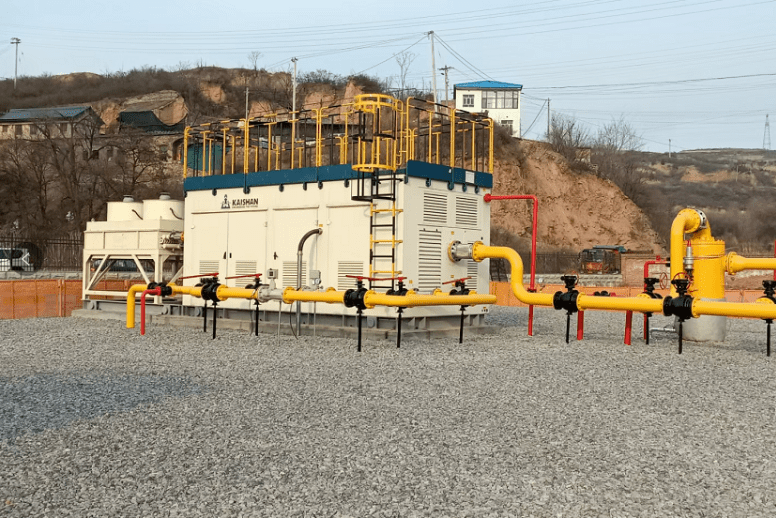

Kaishan Gas Compressor Co., Ltd. has started in the two fields of gas compressors and process compressors at the same time. Taking advantage of the country’s favorable policies for the development of unconventional natural gas, it continues to make efforts in the coal bed methane market. After ten years of unremitting hard work, Kaishan has launched in-depth cooperation with well-known energy companies at home and abroad, and has established a solid market foundation in the Qinshui Basin in Shanxi, which is rich in coal resources.

Coalbed methane compressor

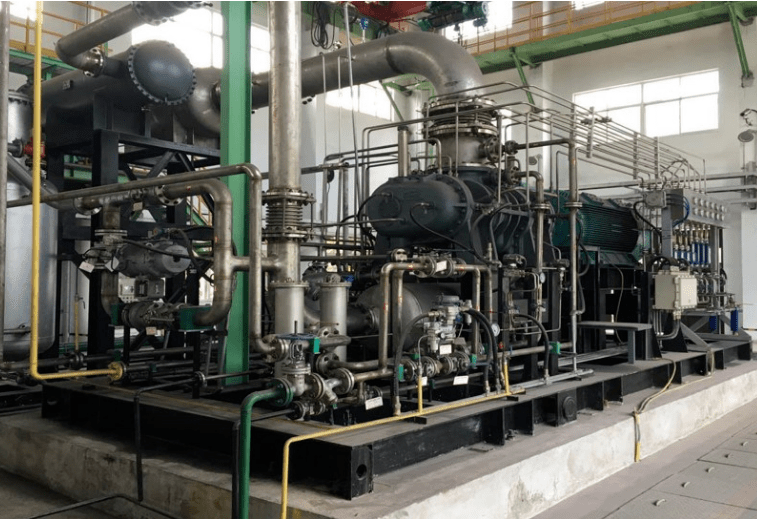

In recent years, as the country has put forward the clear goals of “carbon peaking” and “carbon neutrality”, Kaishan Gas Compressor Co., Ltd. has seized this important historical opportunity and made great efforts in the clean utilization of coal such as coke oven gas, waste gas, Fruitful results have been achieved in the development and application of compressors for hydrogen-containing mixed raw gases such as furnace gas, and breakthroughs have been made in hydrogen energy production and storage applications with a focus on the construction of a hydrogen energy society.

Bayi Steel Plant Ouye Furnace Coke Oven Gas Screw Compressor

At the same time, Kaishan Gas Compressor Company has upgraded its petroleum refining technology and its successful applications in refining tail gas, analytical gas, raw material gas and other fields have also won praise from customers. It has cooperated with Baowu Group, Sinopec, Sinochem Group, Hegang Group, Xinjiang Guanghui Energy, Xindi Energy, Jinneng Holdings, Huaxin Gas, Xinao Gas, Woneng Chemical and other well-known domestic enterprises have established good cooperative relationships.

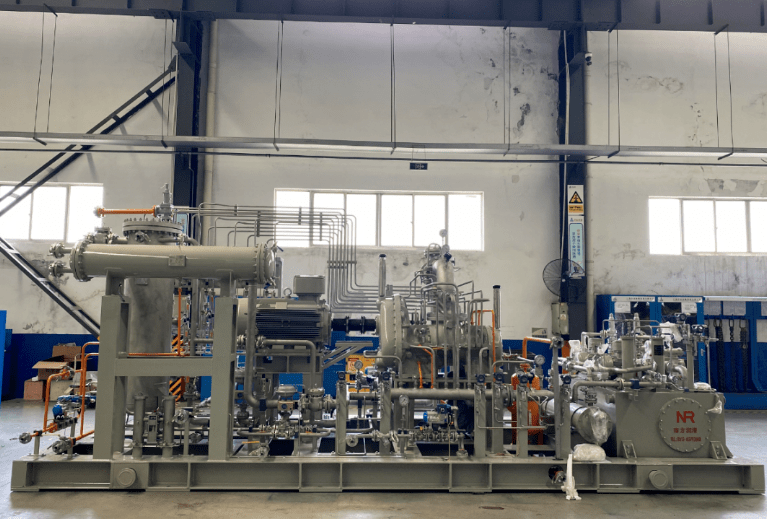

Since 2015, Kaishan Gas Compressor Company has participated in the construction of multiple clean coal utilization projects in Shanxi, Xinjiang, Jiangsu, and Hebei, and has provided customers with oil-free process screw compressors with the largest flow rate and the highest discharge pressure in the industry. Power up to 7400kW.

What is worthy of pride is that the team members of Kaishan Gas Compressor Business Segment are forge ahead and continuously achieve technological innovation, breaking through the limitations of single machine flow and single-stage exhaust pressure of traditional technology introduction and imitation of process screw compressors, and broadening the scope of process screw compressors. The application range of working conditions has brought revolutionary breakthroughs to the traditional chemical process flow, truly achieving what we have when others don’t have it, and what we have when others have it. The “Annual Production of 50 KSG Series Large Gas Screw Compressors Project” won the National Development and Reform Commission’s 2013 key industry revitalization and technological transformation project support plan; the coke oven gas compressor unit successfully applied for the first unit (set) in the key areas of Zhejiang Province’s equipment manufacturing industry in 2014 and outstanding industrial new products. In 2015, the KSG series process gas compressors won the Zhejiang Provincial Science and Technology Plan Major Science and Technology Special Key Industrial Project; the Baowu Group Bayi Steel Reduction Gas Compressor Unit undertaken by Baowu Group, due to its advanced design and stable performance, It has brought a good experience to users and was interviewed by CCTV’s Great Powers and Heavy Equipment column team.

At the same time, under the strategic background of the group company’s global layout, Kaishan Gas Compressor has also sailed overseas and is exported to overseas markets such as Russia, the Middle East, India, Southeast Asia, and Australia.

Looking forward to the future, Kaishan Gas Compressor Co., Ltd. is benchmarking against well-known foreign process compressor manufacturers, accumulating capabilities and making progress. In addition to focusing on screw process compressors, it has also expanded its business to high-pressure reciprocating gases, process compressors and industrial ice machines, seizing the opportunity of China’s advanced manufacturing industry facing a lack of core capabilities and the general trend of domestic substitution to promote the company’s continued growth and strive to It has become an important business growth pole of the group.